Jay Carter V-W Conversion

Jay Carter was one of the most intelligent, nicest, and creative steam people ever. A large book is needed to do him and his work justice, and so this will be a superficial survey. Jay made his money in the oil business in Texas although along the way he made fiberglass hoses for moving oil from remote wells to a collection point. Most of his work was inventing filament wound fiberglass cases for the Polaris A-3 solid fuel rocket motors, both first and second stages, to be fired from nuclear submarines. This resulted in a substantial weight saving over the steel cases that had been standard. Toward the end of his life and in his retirement he designed efficient wind mills that were of the fiberglass, two bladed, downwind design. These |

||

|

were a much better design than the standard Danish three-bladed horizontal-axis upwind turbine design that is in widespread wind turbine design these days. And then, he and his son, Jay Jr., worked on perfecting an autogiro that was cheaper, faster, and safer than a helicopter, mainly because an autogiro is always in auto-rotation. The Carterscopter design could go 450 mph whereas most helicopters are limited to just below 200 mph. It can also take off and land nearly vertically. | |

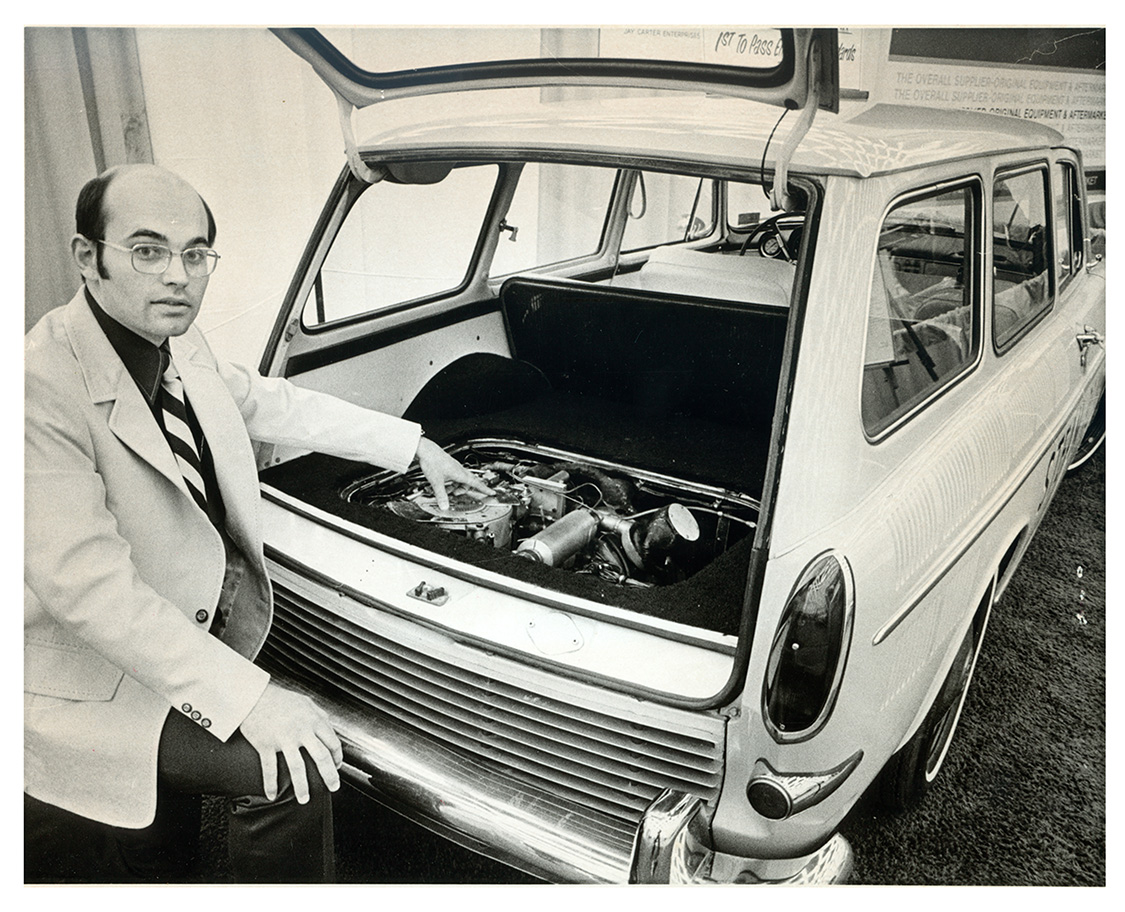

His two steam vehicles were similarly very creative and successful in their design. Jay was always a pilot and he was inspired to think steam while flying into the Los Angeles basin in the 1960’s and could see the thick smog covering the city. He was going to make a steam powered airplane, and so the first design, used in his square back VW, was a four cylinder radial. This was not the optimal design because the lowermost cylinder tended to gather slugs of water. The second design was a two cylinder, in-line, vertical, and so it did not have the water slug problem. |

||

|

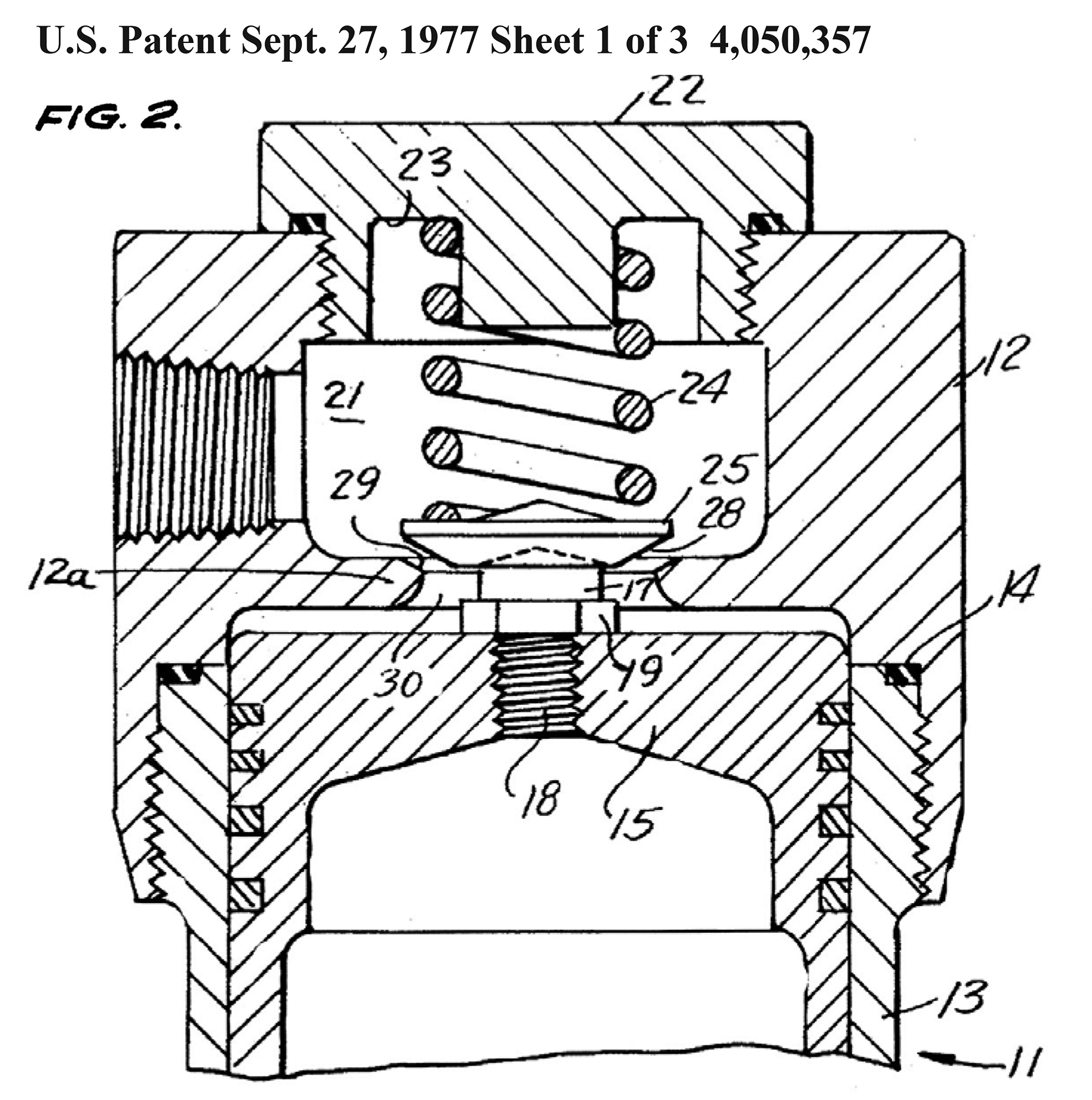

Jay was inspired by model carbon dioxide powered airplanes he made and flew in his youth, and so he was one of the very few people who worked with, and ultimately perfected, the bash valve steam engine. Traditionally, bash valve engines used a steel ball bearing for the valve. Many things happened, with most of them being bad, when a steel ball was bashed. The square-cube rule worked against this design. Metal fatigue and distortion was the main problem. Jay ended up with a titanium Mexican hat design that got around all of the ball bearing deficiencies. |

|

Bash valve patent, Jay Carter |

||

While many steam people start with designing a creative expander (the engine that turns steam pressure into rotary power), Jay did a lot of work with the steam generator (boiler to the common people) and burner. It was a clean burn that was the whole purpose of using steam power in a place, such as the Los Angeles basin. For example, “Black Wednesday” which occurred in September 8, 1943, was the early example there of dangerous air pollution. By 1950 smog was identified as photochemical caused by sunlight, hydrocarbons and nitric dioxide. The Los Angeles basin plus the cool ocean current created a temperature inversion of cool, moist air overlaid by hot, dry air. |

||

| Carter achieved good steam temperature control, something difficult to do with a monotube steam generator, by putting three mercury temperature transducers in the final superheater tube in series in the output steam line, each one controlling a solenoid that injected a small amount of water that cooled the steam, acting as an attemperator or de-superheater. |  |

|

For a steam engine, Carter’s engines used very high pressure and high temperature steam. This worked with the bash valve because they did not require lubrication. The bash valve let in a small amount of steam so that the engine ran at IC engine revs—up to 5,000 rpm. Nor did it require complex valve train. In conclusion, the Mean Effective Pressure (MEP) was similar to that of an IC engine. Therefore, as much of the drive train as possible was borrowed from the IC engine business—clutches, gear boxes, electric starter motor—nothing in the drive train from rear end ratio through the bell housing had to be changed. A centrifugal oil/water separator was developed to keep oil from coating the inside of the condenser. |

||

|

The steam generator had low thermal mass and thus from start to full power was less than one minute. The steam generator had variable pressure control. It was completely safe because of the high strength of the small diameter stainless steel tubing coupled with the very small amount of water in the pressure lines. There was little stored power as there is in a pressure vessel full of hot water, and upon burning out and bursting, a tube only ‘tulips’ when it ruptures—there is no shrapnel and gallons of expanding water rushing out. | |

Jay’s steam car ran for several thousand miles on public roads. Most of the other steam vehicles developed with government money during the clean air craze, ran only on chassis dynamometers and while being attended by several engineers with gauges and computers monitoring the steam power system. |

||

|

|

|

| Popular Science article: Click here. | ||

Jay Carter came as close as anyone did to making a practical steam vehicle. When it was all over he said that having to pack everything into the existing engine compartment of the Volkswagen square back model made engineering development unduly and unnecessarily difficult. A good modern steam power prototype required materials research—metal alloys, metal fabrication, lubrication that would handle high heat and would not homogenize with water, as well as perfect combustion. Carter said that one of the big problems they had was during combustion re-start because a small puff of smoke was emitted at first. There were just a whole lot of problems to solve, at once and in a tight time frame. And then afterwards, these modern steam projects were compared to the current I.C. modern automobile which was the result of billions of development dollars and millions of engineering hours of work over an extended time period of over 75 years. I could go on. |

||

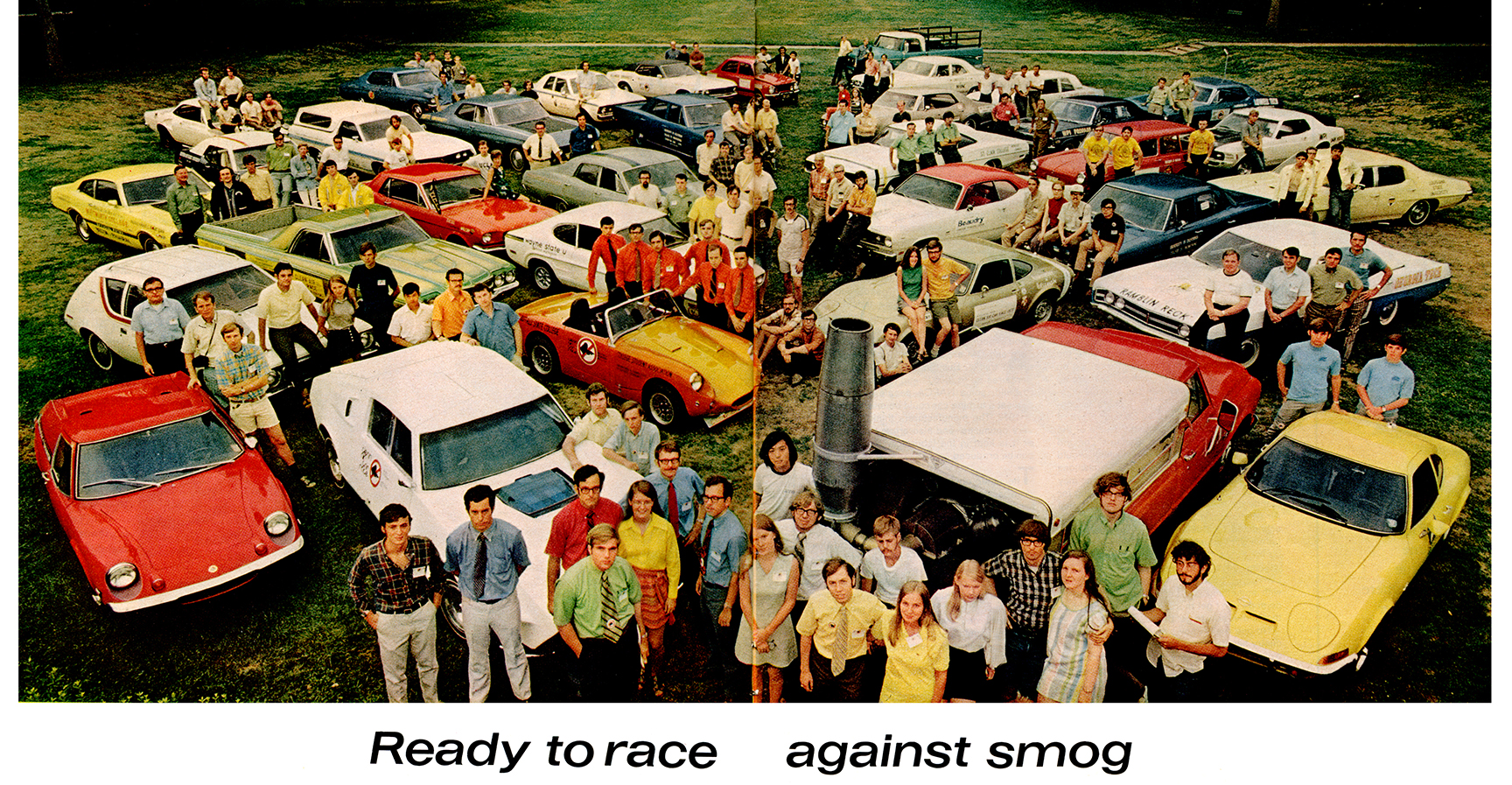

Do some research into the Clean Air Race. |

||

|

||

| Some of the people involved in the clean air race. (Life Magazine, Vol.69, No.10, 1970 Sept, 4) | ||

Read the story HERE! pdf |

||