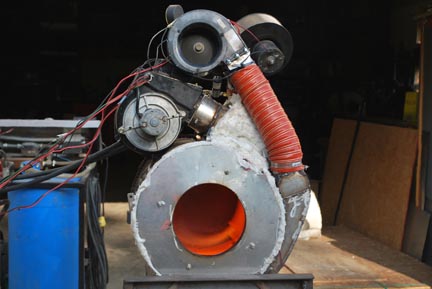

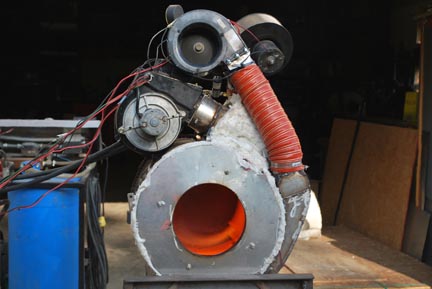

| Motorcycle boiler with test stand and water pump stand on the left. The water pump stand includes two AC powered high pressure water pumps with one of them being variable speed drive. These are controlled also by a by-pass solenoid and two timers that can be set to control the time on and the time off for water flow. |

|

|

| Right now this is wired up with Bob Edwards’ reverse logic that reads last turn temperature and uses that to turn off the Beckett burner. From time to time the burner has had from 3 to 5 gallon per hour kerosene nozzles. |

| |

(Note: Click on a picture to see a larger view and then use your browser to enlarge it further.) |

|

|

Close up of the boiler showing the Beckett burner and combustion chamber about 1” wide and 14” long that wraps around the coil stack. This combustion chamber is made of stainless sheet and glows red hot. There is a plenum on the outside about ¾” thick that has cooling air supplied by two fans. This keeps the outside temperature of the housing below 400 degrees F. |

| |

|

|

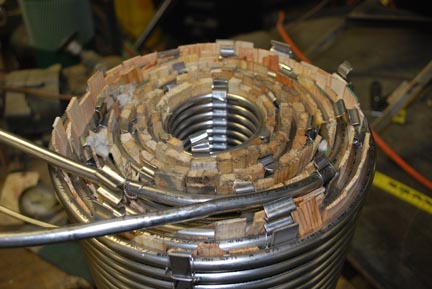

| Because the combustion gas flow is from the outside in, the water flow is from the inside out starting with ¼” tubing. Plenty of flat pieces of metal are built into the coil stack to encourage the combustion gas flow to take a helical pattern. It comes in tangentially and the flat streamlined spacer pieces help it circulate around a few times before exiting out the center. When we have a mis-fire and there is unburned fuel we can see the smoke spinning out from the center, indicating that the gas flow is exactly as planned. |

|

|

| |

|

|

|

|

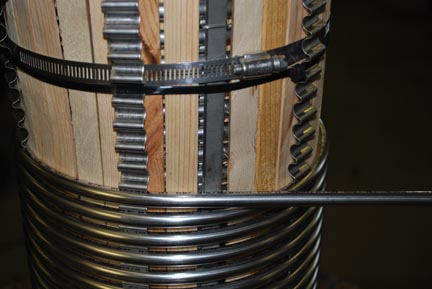

The Stainless tubing is spaced carefully in both dimensions and then wired with stainless wire to hold everything into place. The first manifestations of this coil stack had 900 feet of tubing and this was so much that there was flow resistance to the combustion gases and a far too large economizer section. We were condensing combustion gases on the cold incoming water tubes. The aim is for about a 5 gallon per hour fuel burn and 500 pounds of water evaporated and temperatures and pressures approaching 800 degrees F and 1000 psi. |

| |

|

|

| |

|

|

|

|

|

| Fire in the hole...testing. |

|

|

| |

|

|

| |

|

|

|

|

|

| |

|

|

| Boiler mounted in the motorcycle. |

|

Side view. |

| |

|

|

|

|

|

| |

|

|

| Side rear view. |

|

Side front view. |

| |

|

|